In 1819 a new typefounding firm in Sheffield, Blake Garnett (later Stephenson Blake) bought the hand-typefounding materials of William Caslon IV, of the famous family of type designers. It proved a momentous step. The partners were both skilled craftsmen : one a silversmith, the other ‘Sheffield's best filer’.

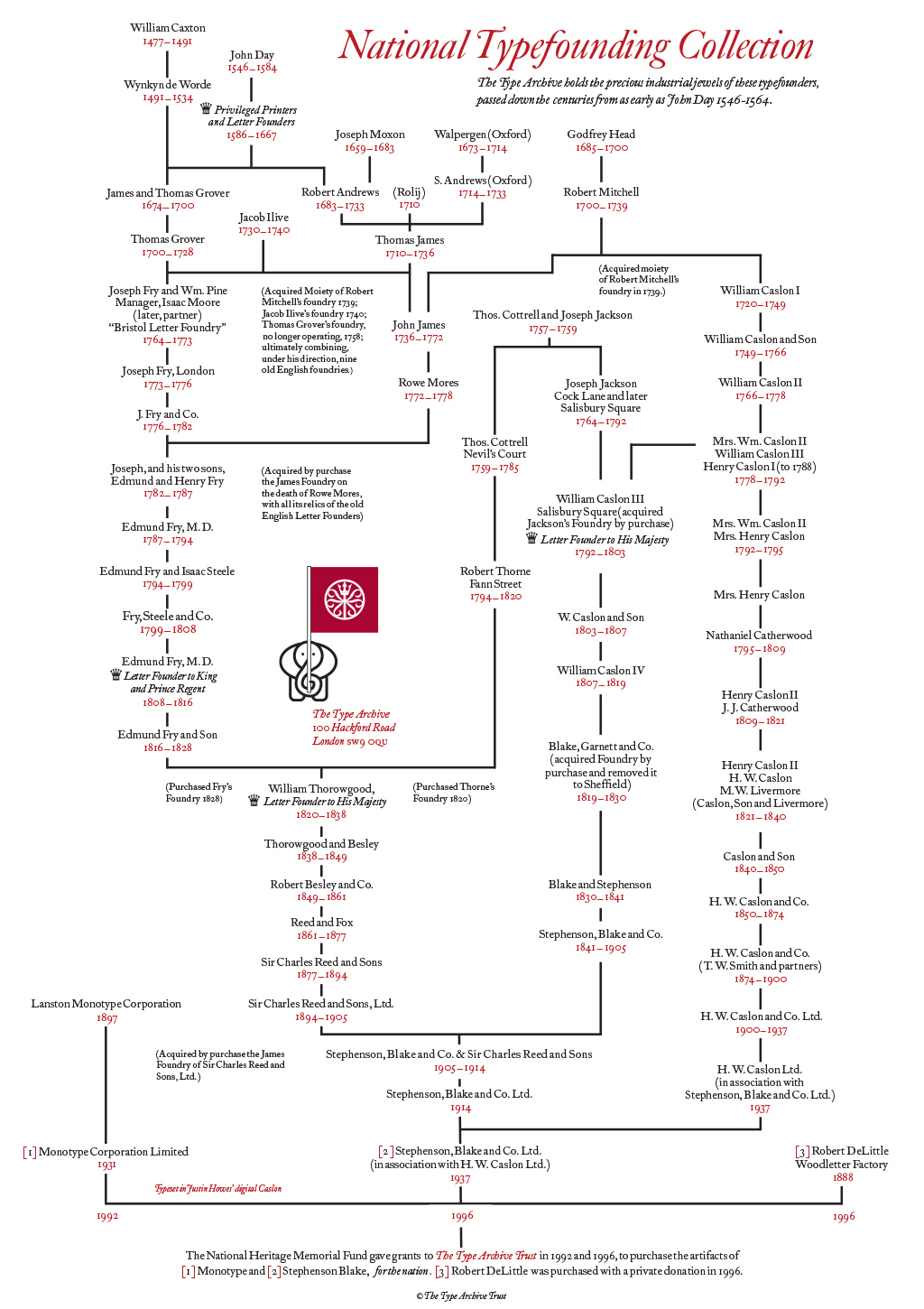

Cutting steel punches by hand was slow and exacting work, requiring rare talent, and typefounders traditionally passed on their precious materials, down the centuries, by descent, or purchase within the trade.

By 1937 Stephenson Blake had absorbed all their competitors, thus acquiring a remarkable range of historic material, some of it dating back to the early 16th century. The irreplaceable artefacts were kept in the great basement of their Sheffield factory, known as ‘The Tomb’.

RESCUE FROM THE TOMB

Sixty years later, in 1996, after many years of negotiation with Stephenson Blake by Susan Shaw, the fount/fonts and documentation were purchased by the Type Archive, with the aid of a unique grant from the National Heritage Memorial Fund, and passed to the care of trustees.

Oxford University Press Hospitality

Justin Howes was appointed Registrar of the move, equipped with 15,000 bar code labels to identify each tray. They were each brought up in a hand lift from the Tomb, emerging slowly from their long seclusion. James Arnold-Baker was kind enough to welcome the collection to Oxford University Press, where they were stored without charge, for two years, while the Type Archive prepared its vault.

Rescue of the Tomb Safes/ the Prism Fund

Later, in 2006, the Sheffield factory was demolished, but not before all the original cabinets and safes were removed to the TA, and each font was returned to its original cabinet by Howard Bratter.

Justin Howes catalogue / the Pilgrim Trust

Justin Howes, the most expert scholar on Stephenson Blake, with a grant from the Pilgrim Trust, prepared a Preliminary Catalogue of the SB collections before his untimely death at 41 in 2005. It was a miracle that he completed the catalogue, just as the SB collection itself is without historical precedent.

The PRISM Fund's grants for moving all the TA collections have been central to its success.

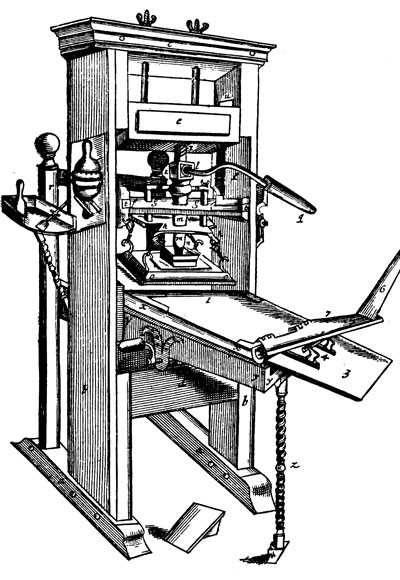

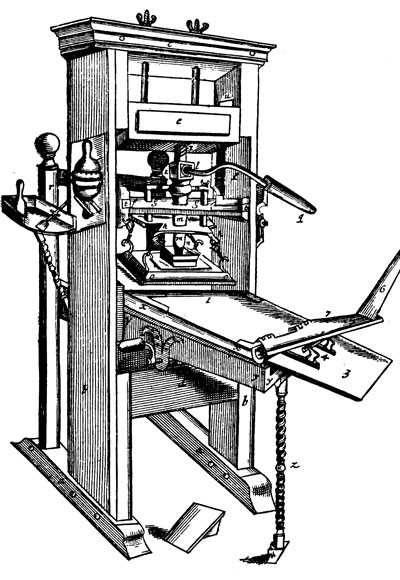

The printing press depicted here is around 1680, and lacks some perspective, making the hazardous ‘bed’ of the press look as though a ‘forme’ would slide onto the floor. The array of parts of the press are given here. Printing presses and printing equipment are traditionally described in very human terms : a. the feet; b. the cheeks; c. the cap; d. the winter; e. the head; f. the till; g. the hose; h. the hooks; i. part of the worm below the head; k. l. the eye of the spindle; m. the shank of the spindle; n. the toe of the spindle; o. the plattin tied on the hooks; p. the bar; q. the handle of the bar; r. the hind-posts ; s. the hind-rails; t. the wedges of the till; u. the mortesses of the cheeks; x. the carriage; x. the outer frame of the carriage; y. the wooden-ribs on which the iron-ribs are fastened; z. the stay of the carriage, or the stay.

1. the coffin; 2. the gutter; 3. the planck; 4. the gallows; 5. the tympan; 6. the frisket; 7. the points; 8. the point screws.

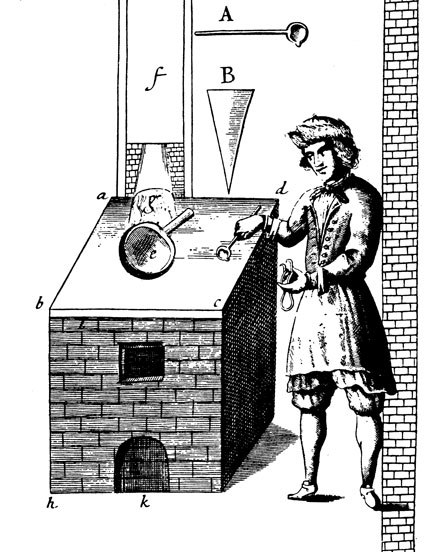

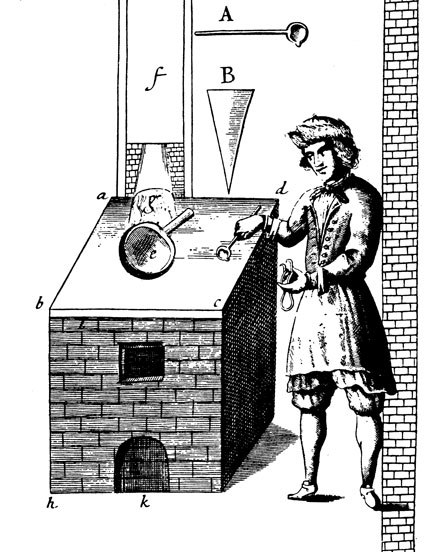

Foundry man setting up the furnace in the 1680s.

A. The letter-ladel; B. the leather of the matrix; a b c d. the square stone at the top covering the whole surface; e. the round hole the pan stands in; f. the funnell (7 inches high and 5 inches wide); g. the stoke hole (4 inches wide and six inches long); h. the height of furnace (2 feet 10 inches); k. the ash-hole. The casting mould held in the founder's hand is not labelled.

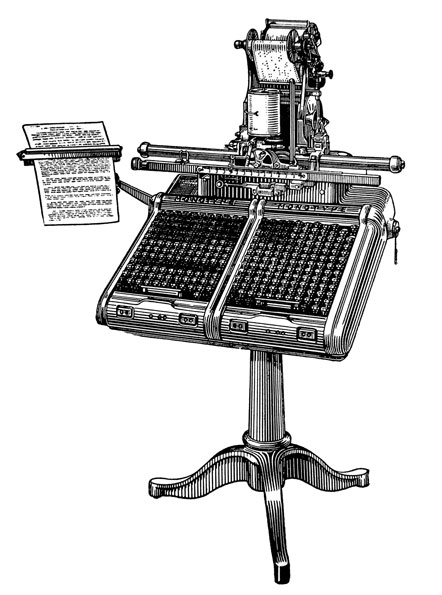

A compositor lifting a heavy ‘forme’ of eight typeset pages. The flat pages are laid out, and ‘imposed’, on a perfectly flat surface, called a ‘stone’. When satisfied that all is accurately positioned, the compositor places a metal frame or ‘chase’ around the pages, fills in all the gaps with ‘furniture’ and locks up each page securley with a ‘quoin’ or wedge. When complete, the chase and pages together become a ‘forme’, which is locked up very tightly and taken to the printing press. Placed on the flat ‘bed of the press’, the job is now ready to run. The machine ‘minder’, the man whose skill determines the success of the final result, then takes over. In due course the printed sheet will be ‘backed up’ with eight more fresh pages, imposed to produce a folded 16 page ‘section’, or ‘signature’. It is impressive team work.

When printed, the reverse process of dismantling the forme takes place on the stone, which is called ‘dropping the forme’, an alarming term. In early printing, the compositor would routinely ‘diss’ (distribute) the individual letters back into the typecase. An exacting and unpopular job, but crucial to future accurate composition: a compositor typesetting by hand at speed, looks at his copy, not at the individual letter sections.

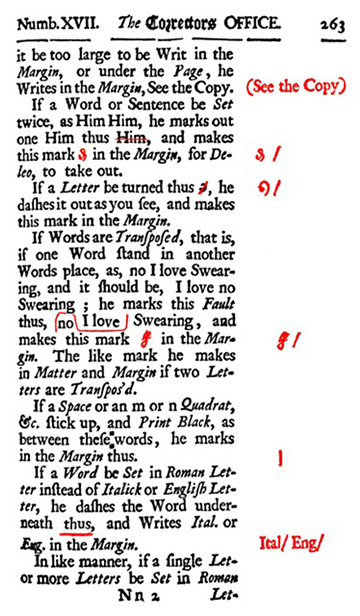

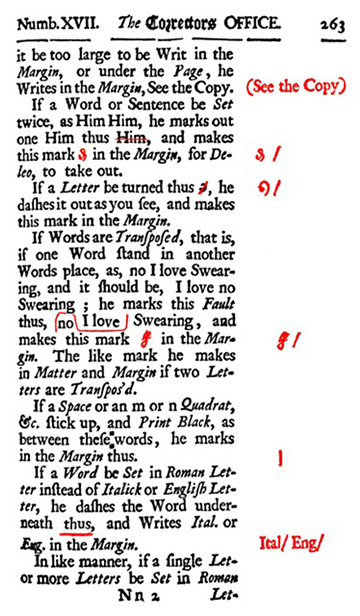

1683 proof reading in the ‘Correctors Office’ indicated little has changed in letterpress. A rough piece of entertaining printing.